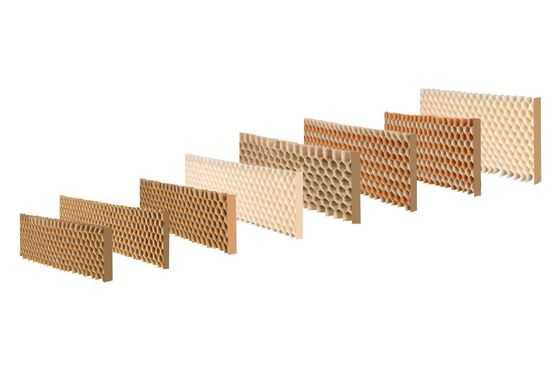

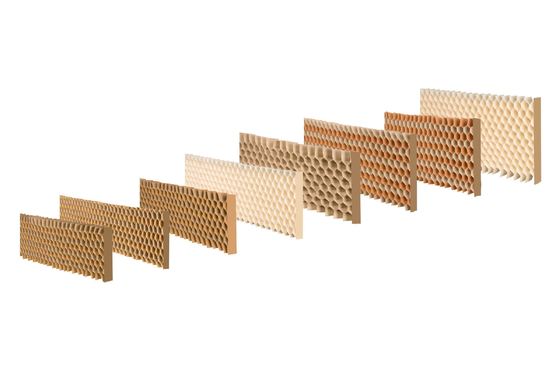

Fire Resistant Paper Honeycomb Core Honeycomb Materials Cell Size 25mm Low Cost

1. Descriptions:

The production process of paper honeycomb core typically involves several key steps:

1. Material Preparation:

- Recycled paper is sourced and processed. This may involve pulping the paper to create a slurry.

2. Sheet Formation:

- The paper slurry is formed into sheets using a paper-making machine. These sheets are dried and cut to the desired size.

3. Honeycomb Structure Creation:

- The sheets are then cut into strips, which are glued together in a zigzag pattern to form the honeycomb structure. This is often done using a specialized machine that folds and bonds the strips.

4. Curing:

- The glued honeycomb structure is cured to ensure that the adhesive sets properly, providing strength and stability.

5. Trimming and Finishing:

- The honeycomb core is trimmed to the required dimensions. Any excess material is removed, and the edges are smoothed.

6. Quality Control:

- The finished honeycomb cores undergo quality checks to ensure they meet specified standards for strength, weight, and dimensional accuracy.

7. Packaging:

- Finally, the paper honeycomb cores are packaged for shipment to manufacturers who will use them in various applications, such as doors, furniture, and partitions.

This process allows for the efficient production of lightweight, strong, and eco-friendly honeycomb cores suitable for a variety of uses.

2. Specifications:

| Paper honeycomb core |

| Material |

Normal paper, fire resistant paper, white vergin pulp fireproof paper |

| Paper Gram |

120g, 140g, 170g, 185g |

| Cell Size |

10mm, 15mm, 20mm, 25mm |

| Dimension |

as request |

| Tolerance |

±0.2mm(Honeycomb Core Thickness) |

| Supply form |

Strip form, continous form, expanded form |

| Package |

Wood pallet |

| Application |

Filing door |

| MOQ |

1000pcs |

| Advantage |

High strength |

3. Paper honeycomb core has several advantages:

• Light specific weight, high strength and high rigidity

• Sound insulation, thermal insulation, moisture resistance and no poison

• Good shock-resisting performance and high bearing capacity

• Environment-friendly and resources-saving

4. Applications:

• Door Filling

• Furniture Filling

• Partition Panel Filling

• Packing

5. Paper honeycomb core of more pictures:

6. Company profile

Suzhou Beecore Honeycomb Materials Co.Ltd, it is the world's leading professional manufacturer of honeycomb materials. Since it' s established, the company has been committed to the research and development of honeycomb technology, from slant-porous aluminum honeycomb core, honeycomb core, honeycomb panel, to the finished product which was using honeycomb panel as the solution, such as truck body, laser TV / projection screen etc.

7. Factory show

8. FAQ

Q1. What is paper honeycomb core usd for?

A: Paper honeycomb core is one of the best filling materials. It has been widely used in door filling, furniture, partition panel filling and packing

Q2. What are the advantages of paper honeycomb core?

A: Paper honeycomb core has the advantages of light weight-high strength, environmental protection and no pollution, good shock-resisting performance and high bearing capacity, resources-saving.

Q3. What is the packaging method of paper honeycomb core?

A: Paper honeycomb core of samples are packed in cardboard and bulk orders are packed in wood pallet with wrapping film.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!